DRIFTER GROUP

Drifting and tunneling are all different methods and approaches utilized in underground drilling and mining to both drill and blast the rock and support the rock.

Drifting refers to the horizontal tunnel that is dug following, for example, an ore vein. It can, however, also be used to describe small exploratory tunnels used to investigate engineering properties of the rock mass. A third use for the word or smaller cuts made to a rock wall that needs to be excavated, which is then expanded out to cover the whole face of the wall with explosives.

Tunneling, on the other hand, is the general reference to any sort of horizontal excavation of landmass, the goal of which is to produce a tunnel, rather than to dig for minerals. Tunneling can utilize drifting, but also other methods such as forepoling, and is often used for construction purposes.

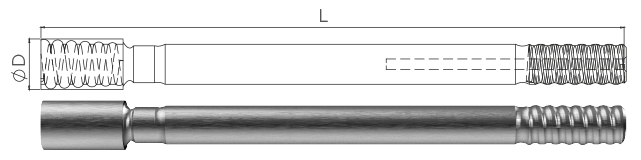

SHANK

Shanks are a durable interface that transmits rotational power to the rods. The shanks we produced have optimum hardness and longer wear resistance. We produce most shank designs of the flagship companies in the market.

| Thread Type | Length (mm) | Diameter (mm) | Thread Width(mm) |

| ISO 10208 R32/R38/T38/T45/T51/T60 | 435 – 990 | 38 – 90 | 6,8 – 20,1 |

JUMBO DRILL BITS

Drilling equipment is produced in variety of materials, designs and equipment, according to formation of soil, surface and rock types. The efficiency of the operation is maximized with the drill bits suitable for the conditions to be drilled.

| Diameter | No of Buttons | Buttons x Button Diameter (mm) | Gauge Buttons Angle | Flushing Hole | ||

| mm | Gauge | Centre | Side | Centre | ||

| 45 | 9 | 6*9 | 3*8 | 20-45° | 1 | 1 |

| 51 | 9 | 6*9 | 3*8 | 20-45° | 1 | 1 |

| 64 | 12 | 8*10 | 4*10 | 20-45° | 1 | 1 |

| 76 | 12 | 8*11 | 4*11 | 20-45° | 1 | 2 |

| 89 | 14 | 10*12 | 6*12 | 20-45° | 1 | 2 |

| 102 | 14 | 10*12 | 6*12 | 20-45° | 1 | 2 |

| 115 | 20 | 12*12 | 8*12 | 20-45° | 1 | 3 |

| 127 | 20 | 12*12 | 8*12 | 20-45° | 1 | 3 |

*We produce any size on your demands.

COUPLING

Jumbo Drilling couplings are adapter equipment used to extend and connect the rods that transmit the drilling process its length, power and rotational motion.

| Thread Types | Length (mm) | Diameter (mm) | Weight approx.(kg) |

| ISO 10208 R25-R32 | 160 | 44 | 1.2 |

| ISO 10208 R28-R32 | 160 | 44 | 1.2 |

| ISO 10208 R32-R32 | 160 | 44 | 1.6 |

| ISO 10208 R32-R38 | 170 | 55 | 2 |

| ISO 10208 R38-R38 | 170 | 55 | 2.2 |

| ISO 10208 R32-T38 | 170 | 55 | 2 |

| ISO 10208 T38-T38 | 180 | 55 | 2.2 |

| ISO 10208 R38-T45 | 180 | 60 | 2.4 |

| ISO 10208 T45-R32 | 180 | 60 | 2.2 |

| ISO 10208 T45-T38 | 180 | 60 | 2.4 |

| ISO 10208 T45-T45 | 180 | 60 | 3 |

| ISO 10208 T45-T51 | 225 | 72 | 4.5 |

ADAPTERS

It is the connecting part used to extend the rods, which is insufficient for long-length drilling operations.

| Adapters | Female Thread | Male Thread | Length (mm) | Diameter (mm) | Weight (kg) |

| R25 F – R32 M | ISO 10208 R25 | ISO 10208 R28 | 173 | 45 | 1.1 |

| R25 F – R28M | ISO 10208 R25 | ISO 10208 R32 | 173 | 45 | 1.2 |

| R28 F – R32 M | ISO 10208 R28 | ISO 10208 R32 | 165 | 44 | 1.5 |

| R32 F – R38 M | ISO 10208 R32 | ISO 10208 R38 | 225 | 45 | 1.8 |

| R32 F – T38 M | ISO 10208 R32 | ISO 10208 T38 | 225 | 45 | 1.9 |

| T38 F – T45 M | ISO 10208 T38 | ISO 10208 T45 | 285 | 57 | 2.9 |

| R38 F – R32 M | ISO 10208 R38 | ISO 10208 R32 | 245 | 55 | 2.2 |

| R38 F – T38 M | ISO 10208 R38 | ISO 10208 T38 | 245 | 55 | 2.4 |

| T38 F – R32 M | ISO 10208 T38 | ISO 10208 R32 | 247 | 57 | 2.2 |

| T38 F – R38 M | ISO 10208 T38 | ISO 10208 R38 | 280 | 57 | 2.7 |

| T45 F – T38 M | ISO 10208 T45 | ISO 10208 T38 | 265 | 63 | 2.9 |

| T45 F – T51 M | ISO 10208 T45 | ISO 10208 T51 | 285 | 63 | 3.6 |

| T51 F – T45 M | ISO 10208 T51 | ISO 10208 T45 | 285 | 71 | 4 |

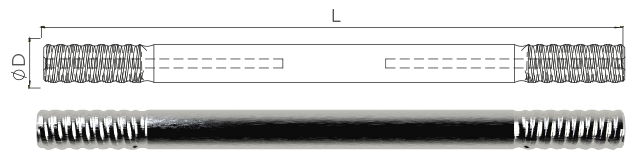

ROD

Rod is the equipment that provides the length, transmits the rotational motion and the striking force to perform the drilling process in Jumbo drills.

| Thread Type | Rod Length(mm) | Rod Type |

| ISO 10208 R32/R38/T38/T45/T51 | 1830 – 6095 | Round / Hexagon |